ArcelorMittal Europe – Flat Products

ArcelorMittal Europe – Flat Products

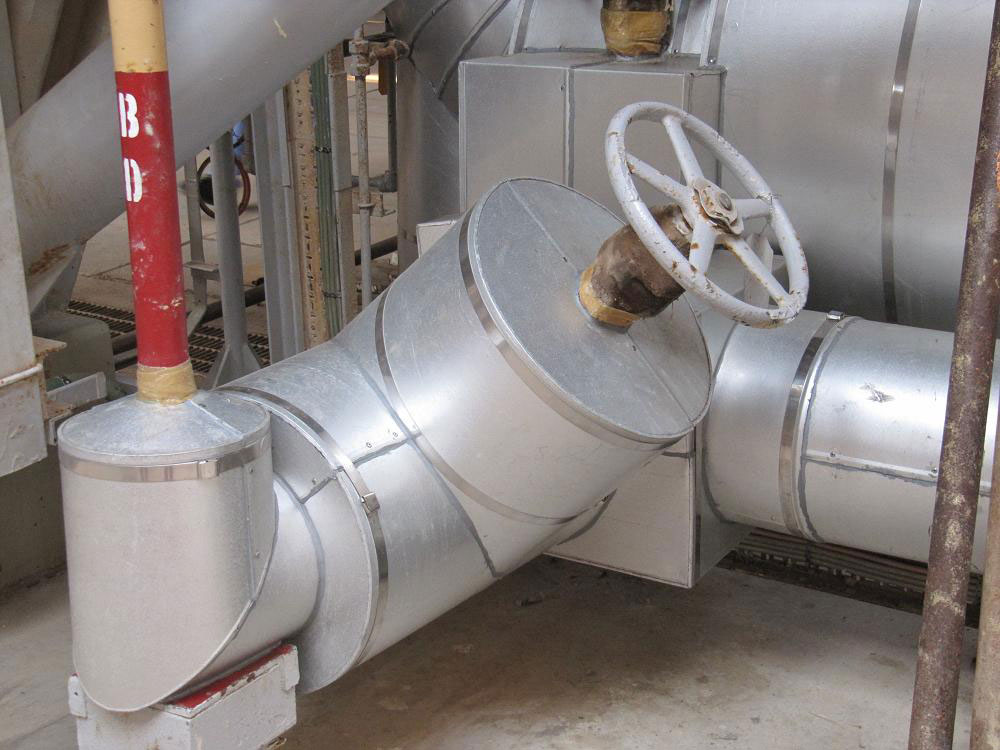

The new jackets will insulate, weatherproof, and enhance the fire resistance of the ADGAS infrastructure on Das Island. That includes all equipment used in cold, cryogenic, cyclic, and elevated temperature operations. The new jackets also had to meet strict local safety specifications.

“It’s not just pipes that get jackets,” notes Husam Mahmoud Al Alkhateeb, general manager of the Abu Dhabi Construction Company (ADCC). “They are also used to protect vessels, tanks, pumps, and compressors. And they can be very large – one of the biggest vessels is 70-metres high, and we had to jacket a tank with a diameter of 25 metres.”

But when it came to choosing a material for the jackets, there was only one obvious choice – Aluminized Type 2 (T2) from ArcelorMittal. “This was the same material ADGAS used in 1992-93 when they installed the existing jackets,” says Mr Al Alkhateeb. “Aluminized T2 has a proven track record with oil and gas companies and it is widely utilised as a result. It offers the best value for money.”

Mr Al Alkhateeb believes that ADCC has a responsibility to insist on the use of top-quality materials such as Aluminized T2: “Clients sometimes ask us to use cheaper, inferior products, but cheap is cheap. It will not provide long-term service and that doesn’t go with our ethics. We do something right, or we don’t do it at all. We’ve been in this business for 50 years, we want to be doing it for at least another 50.”

ADCC offers a six-year warranty for jackets made with Aluminized T2. “In fact, it lasts much longer,” explains Mr Al Alkhateeb. “The jackets we are replacing were originally installed in 1992 and 1993, and they have been in continuous use ever since.

And will Mr Al Alkhateeb recommend Aluminized T2 to ADCC in another 20 years: “I think so – ArcelorMittal’s Aluminized Type 2 has stood the test of time and we know it won’t fail. We will continue to use this product in the future. It is definitely here to stay!”

For more information, please