ArcelorMittal Europe – Flat Products

ArcelorMittal Europe – Flat Products

Based in Houston (USA), Quality Tubing produces coiled, high strength steel tubes used in oil- and gas-well interventions and shale hydrocarbon extraction. The company’s latest product is QT-1400, a high strength coiled tube for oil and gas applications.

Developed in close partnership with ArcelorMittal Europe – Flat Products, QT-1400 is the most advanced, and strongest solution on the market today.

Quality Tubing, a part of NOV’s Intervention and Stimulation Equipment business unit, introduced its first coiled tubes for oil-well applications more than 40 years ago. Known as QT-700, the first product had a strength of 700,000 pounds per square inch (psi). With the introduction of QT-1400 in 2016, the strength of these tubes has effectively doubled. This allows Quality Tubing’s customers to significantly reduce tube weight, or increase tube diameter, without affecting performance.

The new product was developed with ArcelorMittal Fos-sur-Mer (France) as Kevin Elliott, senior metallurgist for Quality Tubing explains: “We showed the Fos team what we needed from the steel. Our only specification was that they should use a high strength, low alloy (HSLA) grade. Fos came back with an alloy design and samples which we tested in our processes. The alloy they supplied was ready to go from day one.”

The development of the QT-1400 alloy was completed in less than a year by the team at ArcelorMittal Fos-sur-Mer (France). “After several years of limited development of coiled tubing steel grades, we began to work with Quality Tubing in 2010 to design more complex grades. This led to the development of QT-1300 and then QT-1400,” explains Pierre Fize, global account manager for ArcelorMittal.

Although the oil and gas market is subdued, Kevin Elliott expects QT-1400 will become one of Quality Tubing’s leading products: “QT-1400 has received a warm reception from customers. We expect demand for it to grow quickly once oil prices start to recover.”

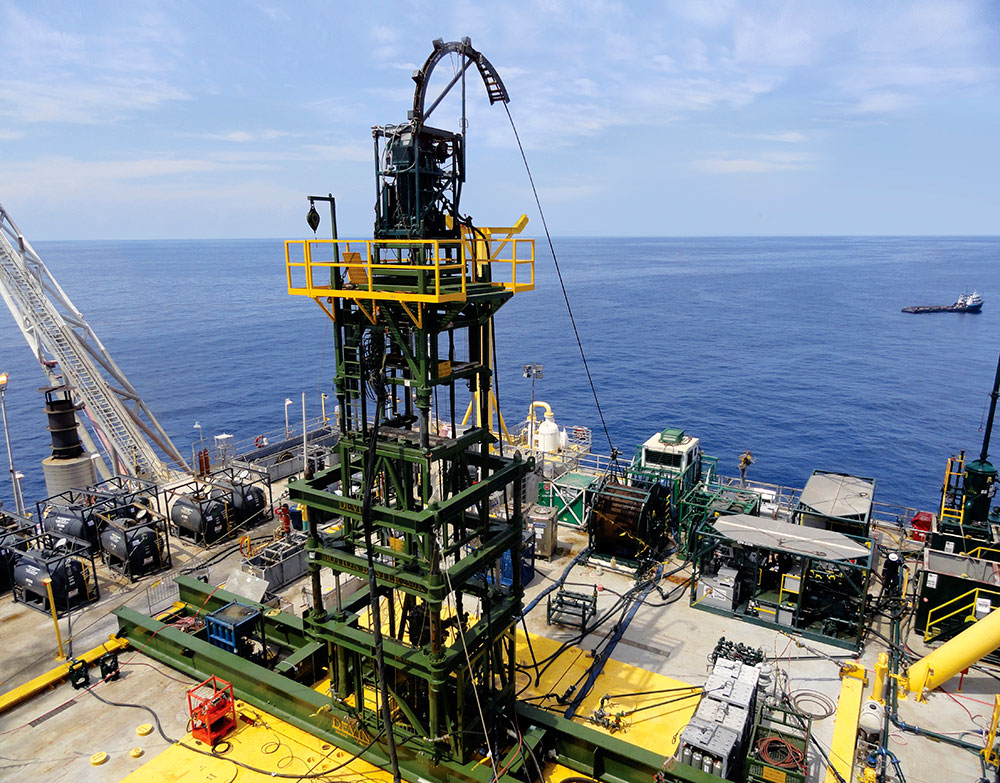

QT-1400 can be utilised in deep, high-pressure oil and gas fields offshore

QT-1400 can reduce string weight, making it ideal for offshore installations where the lifting capacity of rig cranes is limited

Up to 35,000 feet (10,668 metres) of coiled tubing can be spooled onto each reel

For further information about this project and about how our welding expertise and R&D involvement kicked off

a long-lasting relationship with Quality Tubing, please click