ArcelorMittal Europe – Flat Products

ArcelorMittal Europe – Flat Products

Ben Holmes, Senior Commodity Manager for GE Vernova

To create its highly efficient products and services, GE Vernova makes extensive use of electrical steels produced by ArcelorMittal Europe – Flat Products. While most of these steels are used in Europe, the resulting products are deployed worldwide.

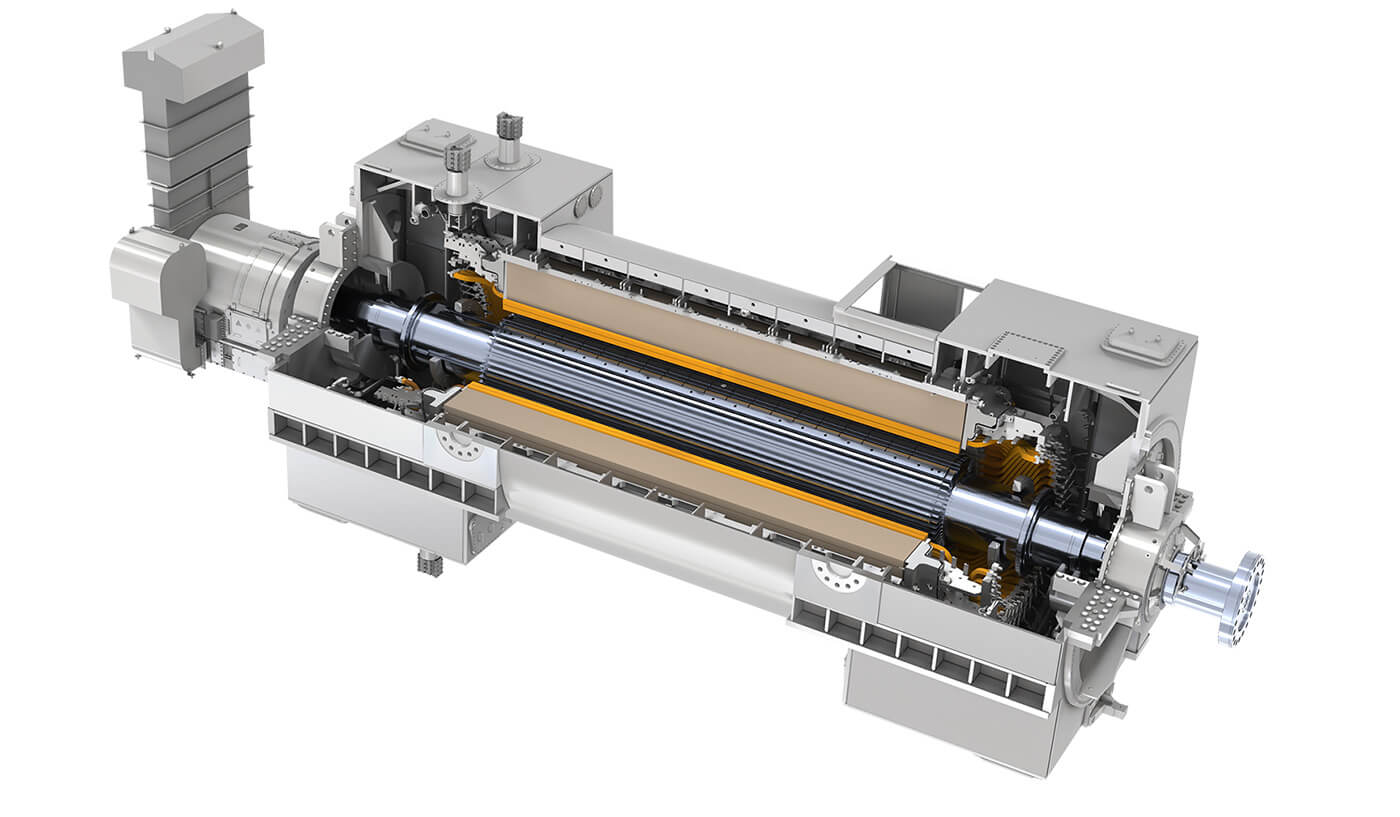

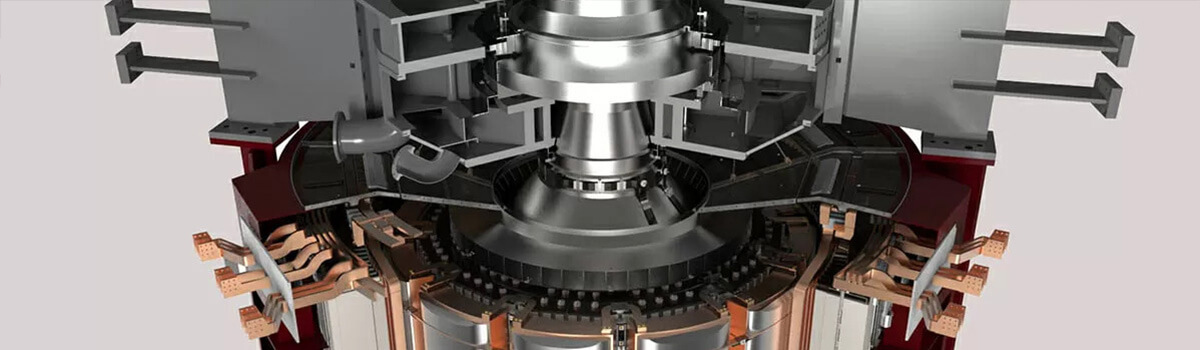

The relationship between ArcelorMittal Europe and GE Vernova is built on legacy gas turbine generators which convert natural gas to electrical energy. Today that focus has shifted to alternative fuels, like hydrogen. Ben Holmes, Senior Commodity Manager for GE Vernova, explains: “GE Vernova is active in every energy generation segment and provides solutions needed for the energy transformation. We also utilise ArcelorMittal’s electrical steels in electrical motors for ships and production equipment. That includes the electrical motors ArcelorMittal utilises in its steel rolling equipment.”

GE Vernova is active in every energy generation segment.

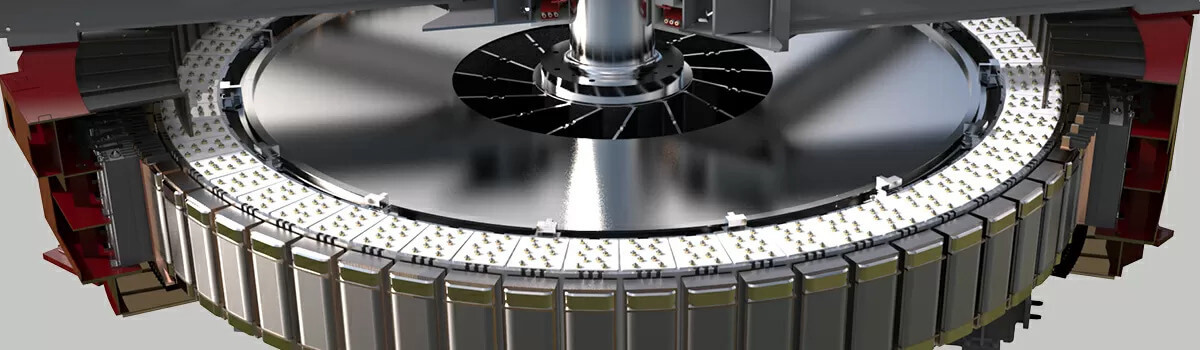

A key growth area is renewable energy. “This industry segment is predicted to grow exponentially over the next five to ten years,” notes Ben Holmes. “It will lead to significant additional demand for electrical steels in the years to come. ArcelorMittal’s investment in its new electrical steels production facility in Mardyck (France) has the potential to help us aim to meet that demand.”

“ArcelorMittal’s Mardyck announcement came at a time of rapidly growing demand for electrical steels in Europe,” says Ben Holmes: “The new capacity will help GE Vernova to meet the challenges of the energy transition as we move through this decade.

Renewable energy sources such as wind, hydro, and hydrogen are becoming increasingly important to the energy mix.

ArcelorMittal’s ability to provide narrower widths reduces internal process costs significantly.

“A key advantage of ArcelorMittal’s current offerings is the diversity of steel grades and sizes” notes Ben Holmes.

“We’re constantly looking for opportunities to provide better performance to enhance the efficiency of our electrical machines,” says Ben Holmes. “The ArcelorMittal Europe team continues to provide support with a view to developing new electrical steel products. ArcelorMittal are positioned to potentially have a key role to play in our supply chain.”

To read the full article, please

Click here