ArcelorMittal Europe – Flat Products

ArcelorMittal Europe – Flat Products

Advanced high strength steels: designed to save lives

To build a more sustainable future, we need to improve what we make, how it is made, how we use it, and how it is reused or recycled in the future. That’s is why ArcelorMittal uses life cycle assessment (LCA) to benchmark our production processes and measure how our products and solutions are becoming more efficient and sustainable.

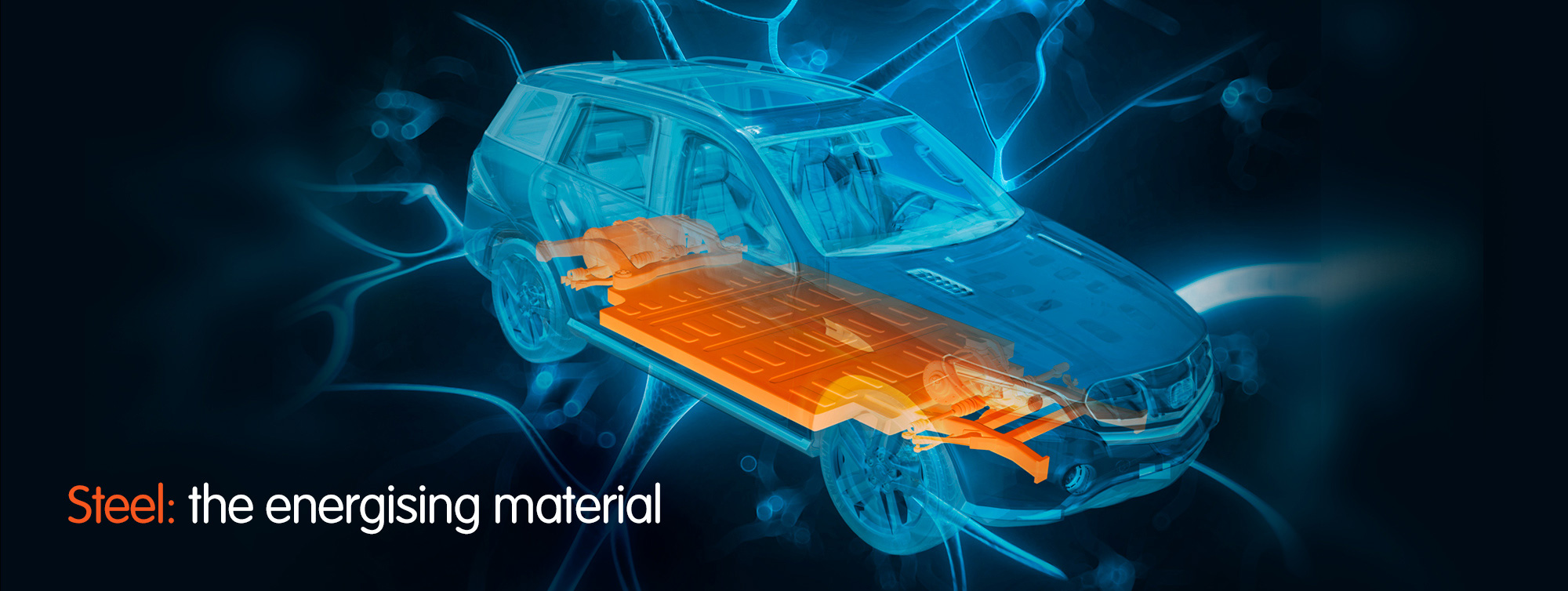

If you look at the entire lifecycle of a vehicle, steel is already the most sustainable material to make efficient and affordable cars. That’s partly thanks to the fact that steel already has much lower CO2 emissions in primary production than competing materials. In the use phase, the most advanced steels perform even better than other materials, particularly when it comes to passenger safety.

And in the end-of-life phase, steel outperforms any other material due to the ease with which it can be recovered and recycled. That’s why steel is the most recycled material in the world.

Adopting an LCA approach to assess the environmental advantages of different materials highlights these benefits. And it encourages innovation in all parts of the vehicle and all phases of its life – from raw material selection to end-of-life recycling.

| Part weight (kg) | kg CO2eq/part (production only) | |

|---|---|---|

| Mild steel HDG | 100 |

|

| AHSS HDG | 75 |

|

| Aluminium | 60 |

|

| Magnesium | 50 |

|

| CFRP | 45 |

|

Relative global-average emissions of different automotive body materials [Adapted from World Auto Steel]

Despite LCA being an ISO standard, and widely used by industry, there is no link between LCA and current regulatory policy. Instead, the main automotive emissions considered are tailpipe emissions. As a result, the lighter car ‘wins’ because the use phase is the only part of the vehicle’s life which is considered.

Assessing the environmental impact of materials at every stage of the vehicle’s life is the only way

to gauge their full environmental impact [Source: worldsteel]

To provide a neutral basis for material selection, LCA should be used. In late 2018, the European Parliament recognised the importance of life cycle thinking when assessing emissions beyond 2020. That will require carmakers to report the lifecycle emissions of new cars from 2025. This change has been welcomed by ArcelorMittal and other steelmakers as it levels the playing field for all materials. ArcelorMittal hopes that these measures will be emulated by regulators across the world.