ArcelorMittal Europe – Flat Products

ArcelorMittal Europe – Flat Products

“In response to the global challenges, the automotive industry is always seeking safer, lighter, and more cost-effective solutions,” says Jesse Paegle, Communication and Development Lead Automotive – Steel Solutions. “But the industry is also looking for more sustainable solutions and ways to simplify vehicle design and production while reducing the size of their production halls.”

ArcelorMittal and AP&T are sharing their expertise to address the need for larger, integrated car parts. Hot stamping MPI solutions will become more efficient than ever before thanks to this cooperation.

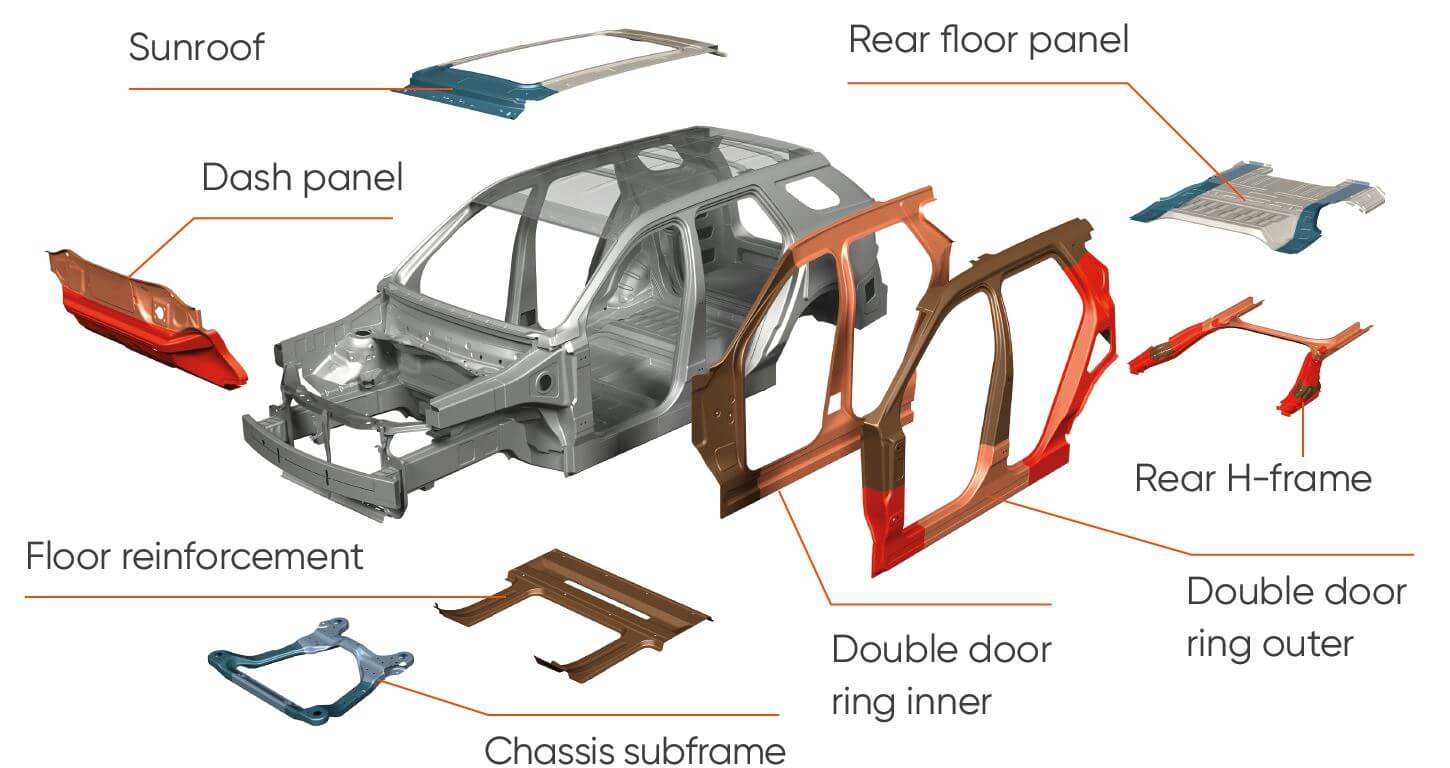

A notable innovation resulting from these efforts is the improved efficiency and scale of ArcelorMittal Multi Part Integration® (MPI) solutions. This approach enables the integration of multiple vehicle components into one very large – or massive – laser welded blank. This reduces the number of parts and simplifies vehicle design drastically.

The original hot stamped door ring innovation, developed in 2014, has now led to a double door ring. Today, MPI solutions such as the

H-frame, dash panel, chassis subframe, and solar roof can replace multiple parts with just one part to streamline production and enhance efficiency.

“Thanks to this collaboration, ArcelorMittal and AP&T have achieved remarkable results. Together we have pushed the boundaries of automotive manufacturing and paved the way for more efficient and simplified vehicle solutions, enabling the efficient production of huge MPI components.”

Jesse Paegle, Communication and Development Lead Automotive – Steel Solutions

AP&T plays a vital role in this partnership, revolutionising automotive production with its state-of-the-art press-hardening equipment. Seamlessly integrating with ArcelorMittal’s steel innovations, AP&T’s multi-layer furnaces and hot stamping presses represent cutting-edge technology.

“We have certainly taken on the challenges related to the production of large parts. Our press-hardening technology is a perfect match for ArcelorMittal’s MPI body components, since this offers low total cost of ownership, low climate impact, and a very small equipment footprint,” says Dr Christian Koroschetz, Head of Products & Marketing at AP&T.

Dr Christian Koroschetz, Head of Products & Marketing at AP&T.

To read the full story and watch the hot stamping video animation on the automotive website, please

Click here