ArcelorMittal Europe – Flat Products

ArcelorMittal Europe – Flat Products

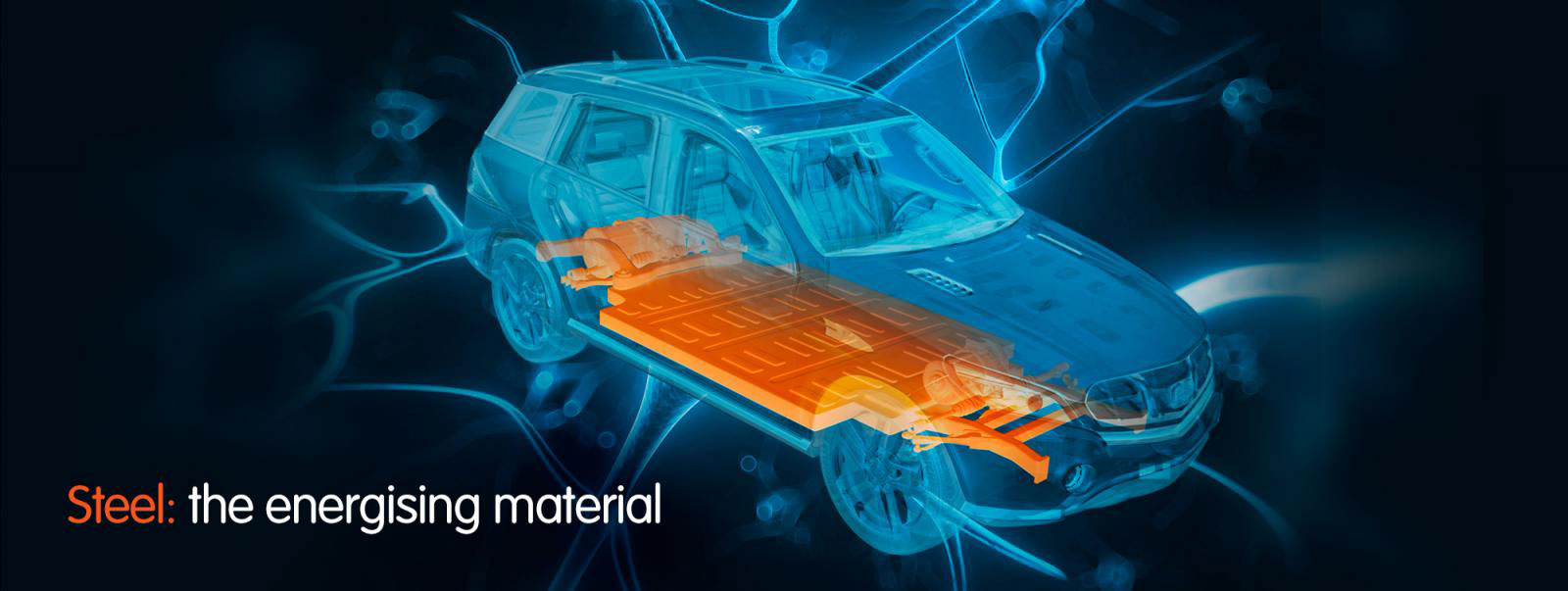

ArcelorMittal is already well positioned to help carmakers respond to this rapid transition to e-mobility. We can offer products and solutions for the body-in-white (BIW), chassis, and e-traction systems. For example, the iCARe® range of electrical steels from ArcelorMittal Europe – Flat Products was designed specifically to meet the needs of electric and hybrid vehicle makers.

To design the new electric models that will be on the road soon, car manufacturers can rely on ArcelorMittal’s full range of steel grades for hot, cold, and roll-forming. We also offer strong Global R&D teams which can accompany our automotive customers as they transition their fleets to include more electric mobility solutions.

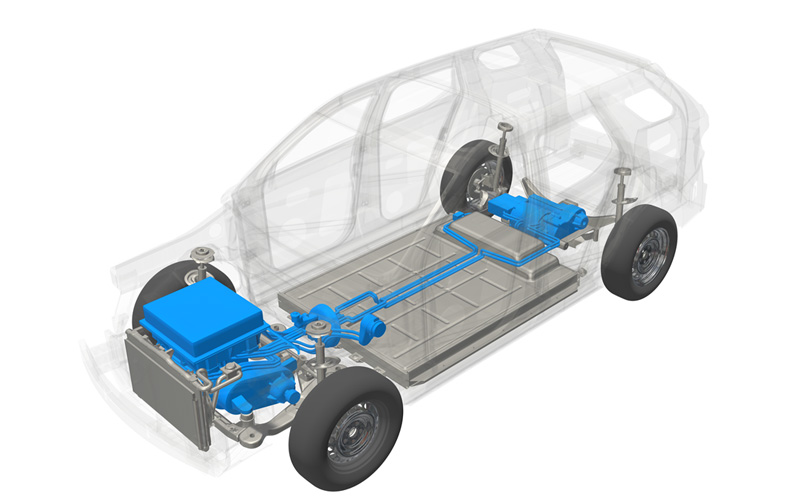

Another industry leading initiative is ArcelorMittal’s S-in motion® programme. One of the latest S-in motion® solutions is for the battery pack of a battery electric vehicle (BEV).

The examination of the battery pack demonstrated how advanced high strength steels (AHSS) can achieve these goals by simulating some of the most severe load cases. The three main sub-modules (upper cross member, frame and lower shield) of the battery pack were shown to benefit from the use of AHSS such as ArcelorMittal’s MartINsite® 1500 steel grade. The MartINsite® grade was able to resist high load-deformation due to its very high yield strength of more than 1200 MPa.

The MartINsite® solution is also more environmentally friendly and cost-efficient than a similar aluminium-based structure. Compared with the aluminium version, ArcelorMittal’s MartINsite® offers a 36 percent reduction in CO2 equivalent emissions and a cost saving of between €80 and 100 per car.

ArcelorMittal offers the most efficient AHSS steels and steel solutions for battery electric vehicles (BEVs). All these solutions have passed extensive assessments, including global crash test simulations, forming feasibility, assembly etc. To discover our customizable BEV steel solutions for body-in-white and battery pack, check out our S-in motion® BEV SUV 3D car configurator