When Czech furniture producer Kovona System started to develop a new office table for Ikea, they required a material with a low coating thickness and good corrosion protection. The solution was Jetskin® from ArcelorMittal Europe – Flat Products, which has a very thin and homogeneous zinc coating. Compared to the hot-dip galvanised material Kovona regularly uses, Jetskin® is easy to weld and offers excellent paint adhesion and aesthetics.

One of Kovona’s initial designs for the table’s legs specified hot-dip galvanised steel which the company often uses for its products. “We tried to work with a steel that had a low-zinc electroplated coating on both sides,” explains Marek Gil, commercial director of Kovona System. “We have had a lot of experience with this material. But in this application, the welds disturbed the visible surface of the zinc-plated steel. It was also difficult to powder coat the inner part of the table legs and we couldn’t use the material without corrosion protection.”

The company was introduced to Jetskin® when their ArcelorMittal client technical support (CTS) manager, Lubomir Petřík, organised a demonstration of the product at Kovona’s plant. “Jetskin® attracted our attention due to its appearance, the homogeneity of the surface layer, and its corrosion resistance,” says Marek Gil. “The environmental advantages were also very important to us and our customer Ikea.”

Lubomir Petřík, client technical support coordinator for ArcelorMittal in Czechia checks coils of Jetskin® in the Kovona System warehouse

Kovona started with a small amount of material which they initially used for corrosion testing. The next steps were to slit the coils into strips, and then cut and profile the material into the final shape. Welding tests were also carried out to ensure the required aesthetic finish could be achieved.

“At the beginning of the project, Lubomir Petřík helped us to obtain samples which were suitable for the comprehensive testing we needed to carry out,” says Marek Gil. “We also worked closely with ArcelorMittal Liège, where Jetskin® is produced, to get more information about the material.”

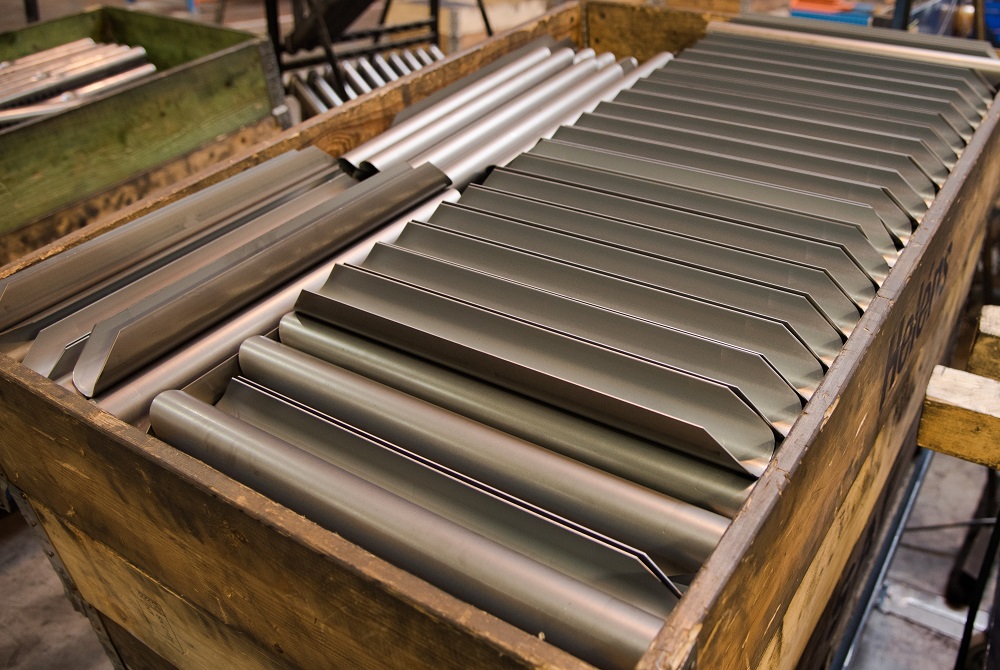

The slit coils are cut and bent into the required shape

The table legs were welded together using an automatic welding machine

As the Jetskin® was already coated on one side, Kovona painted the other side after forming notes Marek Gil: “That enabled us to verify that Jetskin® was the right material for this application. After all processes, including welding and powder coating, everything was perfect and the product was accepted by our customer.”

While Kovona has no specific plans to use Jetskin® in other products, Marek Gil can see its potential: “Jetskin® is ideal for parts which require good corrosion resistance but can’t be electrostatically powder coated – particularly those with cavities or on the inner side of a profile. Based on our current experience, we will not hesitate to use Jetskin® again.”

Ready for use!

Kovona System was founded in 2000 when investors purchased the production assets of Kovona Karvina, a company which can trace its history back to 1904. Today Kovona System manufactures steel profiles, parts for cars, garden equipment, shelving systems, and office furniture from its base in Czechia. They export their products to customers around the world.

More info: https://www.kovona-system.cz/

Jetskin® is a metallic coating for steel which is applied in a vacuum using Jet Vapour Deposition (JVD) technology. In the JVD process, the steel receives a very homogeneous coating of zinc on one or both sides. The depth of the coating can be tailored to a customer’s specific requirements. Jetskin® offers excellent corrosion protection, particularly for indoor applications.

A key advantage of Jetskin® is its low ecological footprint which is due to the efficiency of the JVD process. The life cycle assessment (LCA) for Jetskin® demonstrates significant environmental benefits in terms of global warming potential and the reduced use of resources (in particular, a reduction in fossil fuel use and water consumption) compared to electrogalvanised steel. Jetskin® is fully recyclable in accordance with ISO 14021.

More info: industry.arcelormittal.com/Jetskin

After unwrapping, the coils are ready to be slit

Supports, ready for welding

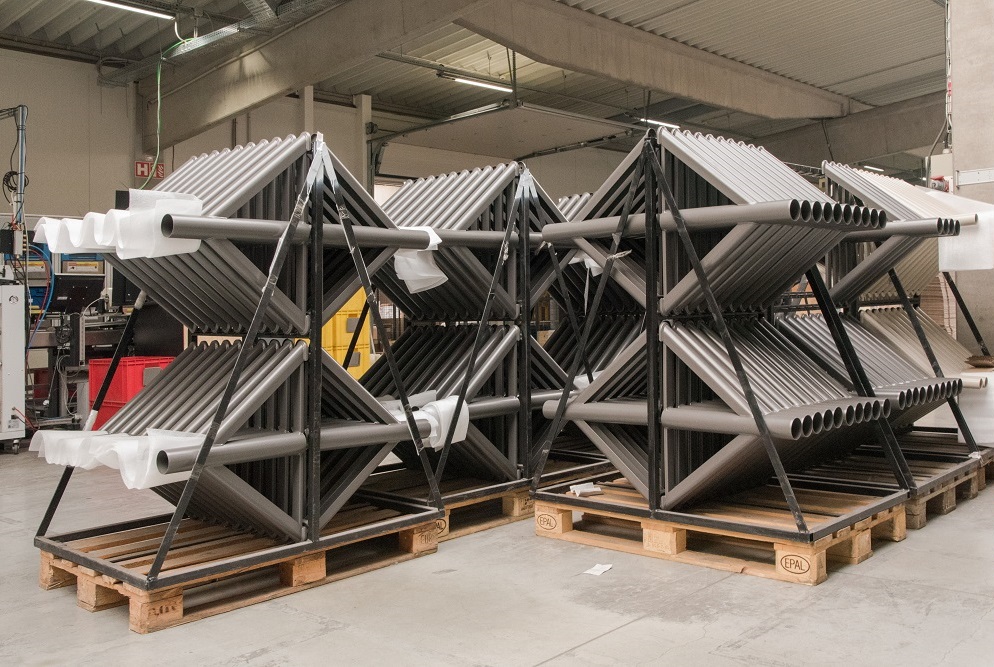

The finished Jetskin® table legs ready for powder coating

The finished table legs ready for packing and shipping to Ikea

Copyright images: Kovona System and ArcelorMittal Europe CZ, s.r.o.