ArcelorMittal Europe – Flat Products

ArcelorMittal Europe – Flat Products

“The outstanding properties of Magnelis®, documented in the DIBt approval, have enabled SCHRAG to make full use of Magnelis® in many applications,” says Gunnar Koelsch, head of purchasing at SCHRAG. “For example, Magnelis® ZM310 is the only zinc-magnesium coating which remains durable for more than 15 years according to DIBt. And the approval covers constructions in zones with a corrosivity rating of C4 under the European norm ISO 12944-2. This is unique.”

Magnelis® also offers excellent protection on cut-edges. After checking the self-healing effect of Magnelis® on cut edges, DIBt concluded that the coating (minimum weight of ZM310) can be utilised with uncoated edges of up to 6.0 mm. The uncoated edges should not have an aesthetic function. This is the only German technical approval for a metallic coating which includes uncoated edges up to a thickness of 6 mm.

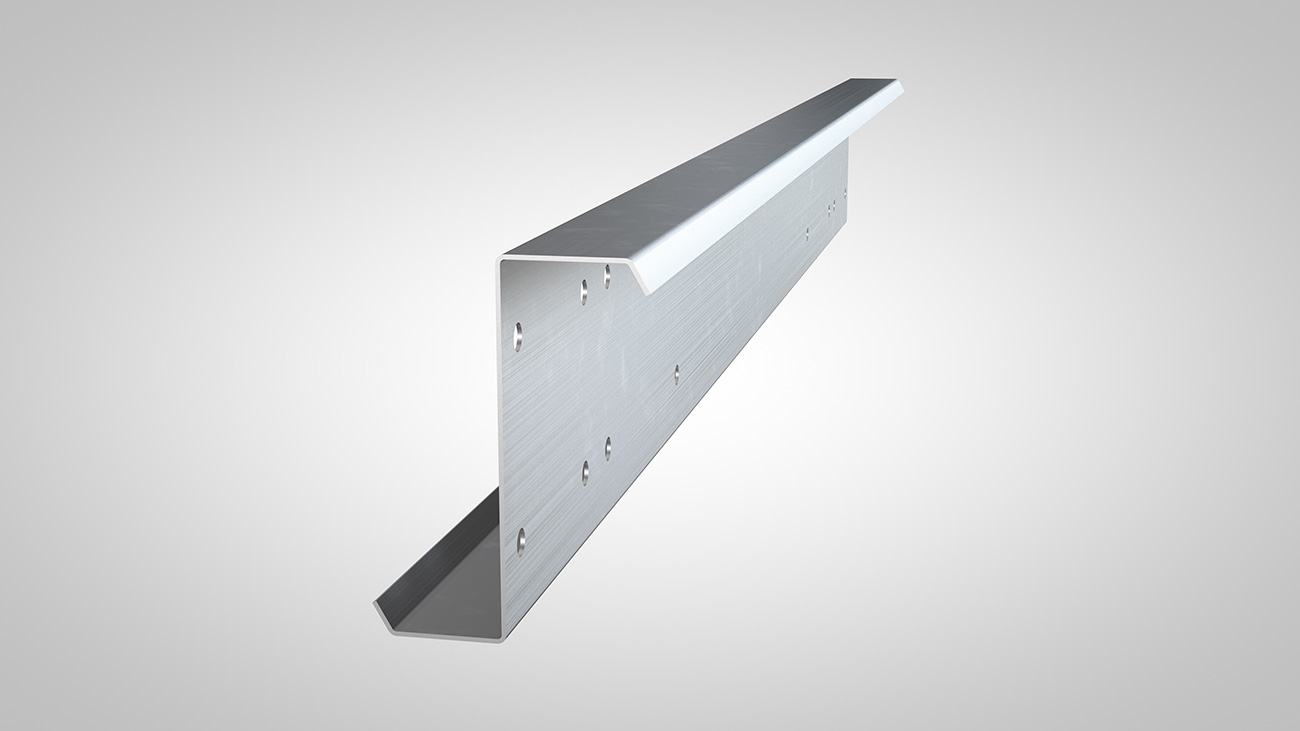

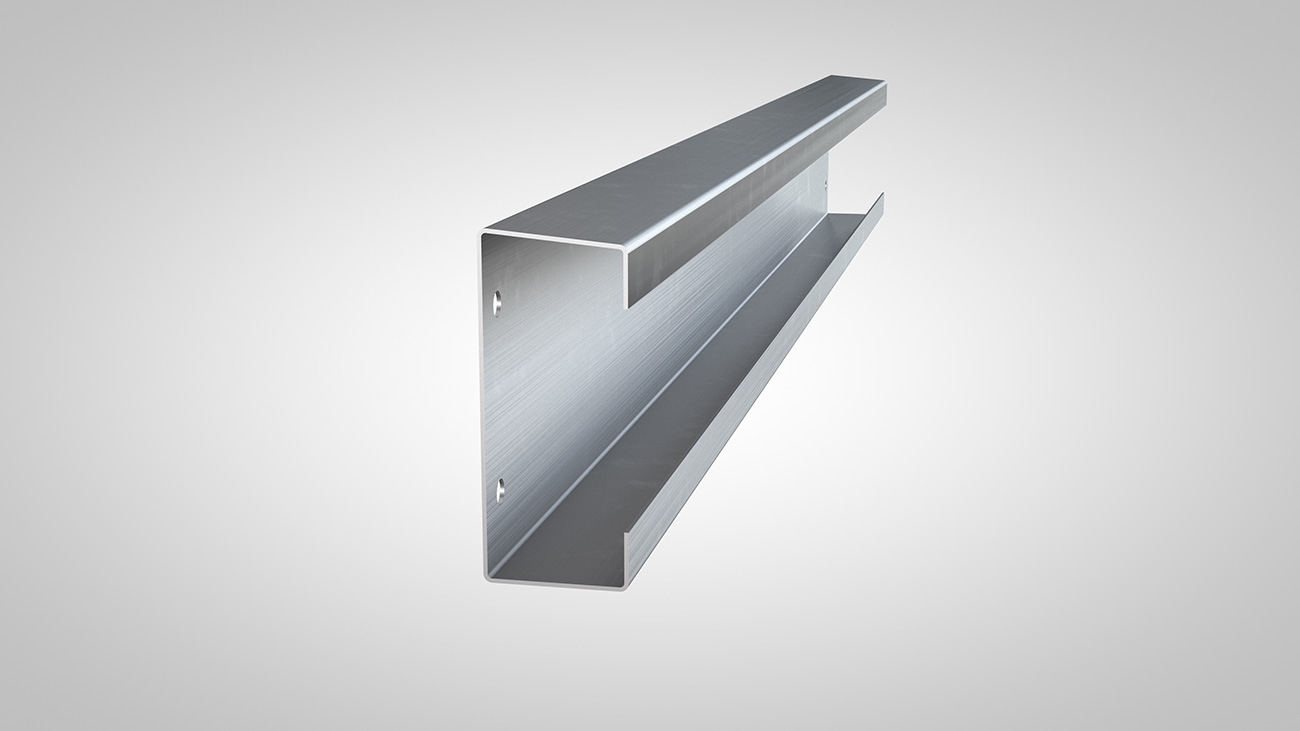

Magnelis® offers cut-edge protection, ideal for SCHRAG’s variable profiles