ArcelorMittal Europe – Flat Products

ArcelorMittal Europe – Flat Products

A unique co-marketing partnership between ArcelorMittal CLN and Prima Power has introduced a new range of customers to ArcelorMittal’s products. The event at Prima Power’s showroom in Italy gave metal-furniture manufacturers the chance to discover both Prima Power’s state-of-the-art machines and ArcelorMittal’s innovative steels and coatings.

Prima Power has developed a unique way to introduce its new generation of machines to customers. Instead of catalogues and virtual presentations, the company has built a

2,500-square-metre showroom in Torino (Italy) where customers can see the machines in action.

In April 2017, more than 300 people from metal-furniture industry from around the world were invited to discover the potential of Prima Power’s technologies. The main focus was on the automatic production line which includes storage and automation solution, punch and shear machines, the panel bender, and combi laser. “We also demonstrated how we can connect our stand-alone machines together to create a continuous line,” notes Matteo Benedetto, vice-president of marketing for Prima Power. “That included some of our latest combi and 3D-laser cutting machines and our Press Brake and Punch Genius machines.”

Special information sessions were held throughout the week so that ArcelorMittal CLN could explain the properties of the steel products being demonstrated. Participants were also able to ask the team technical questions about the steel solutions and their use with Prima Power machines.

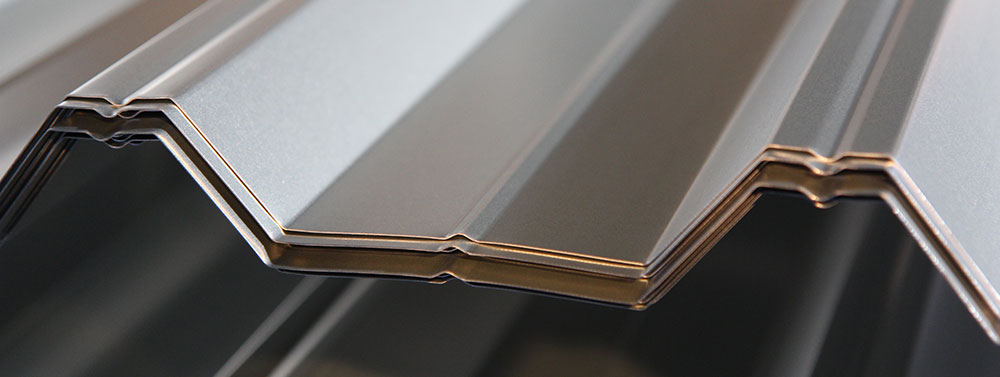

ArcelorMittal CLN supplied Prima Power with the following coated products, which were tested during the demonstration:

A part of ArcelorMittal’s Nature collection, Estetic® Flex is ideal for internal building and general industry applications which require high flexibility such as metal furniture and heating, ventilation, and air-conditioning applications.

An exceptional alternative to electro-galvanised steel thanks to its perfectly homogenous coating.

* The trademark is registered in the EU.

The perfect protective substrate for pre-painted steels.

ArcelorMittal’s leading metallic coating for long-term corrosion resistance.

Over the three days of the Open House, Prima Power machines manufactured dozens of applications including cupboards, electrical cabinets, furniture for cooling systems, and a toolbox that was offered to participants. “Our customers were very impressed,” says Matteo Benedetto. “They come from all over the world so it adds value for them if they can see both the material and the production process at the same time.”

For more information, please