ArcelorMittal Europe – Flat Products

ArcelorMittal Europe – Flat Products

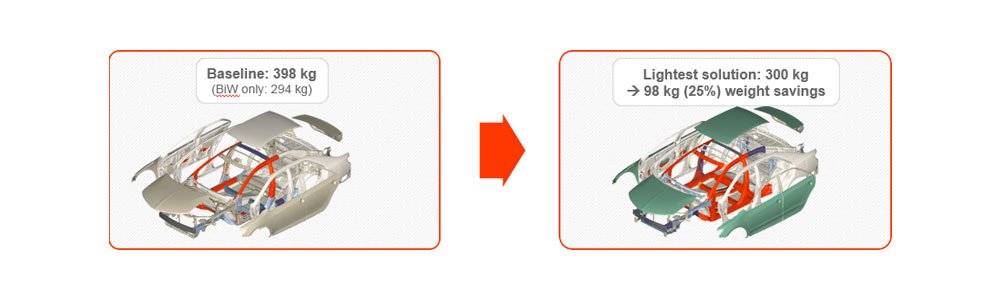

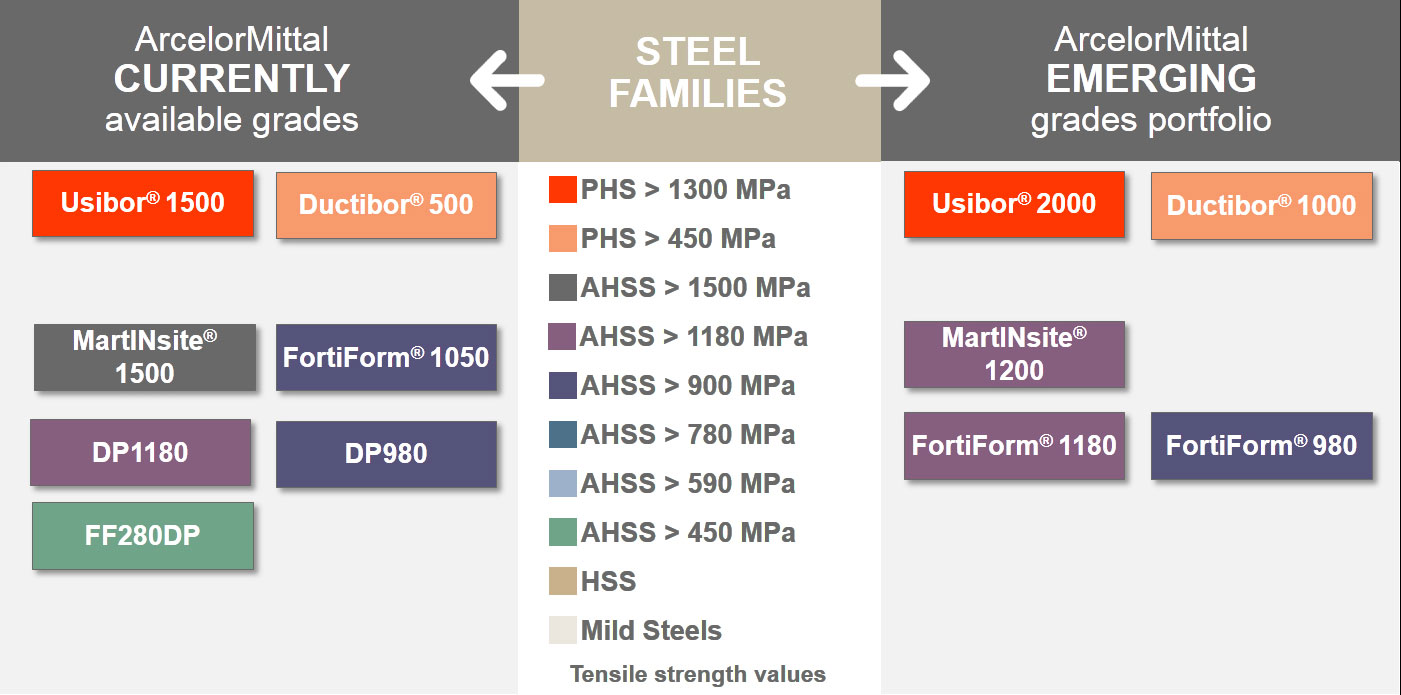

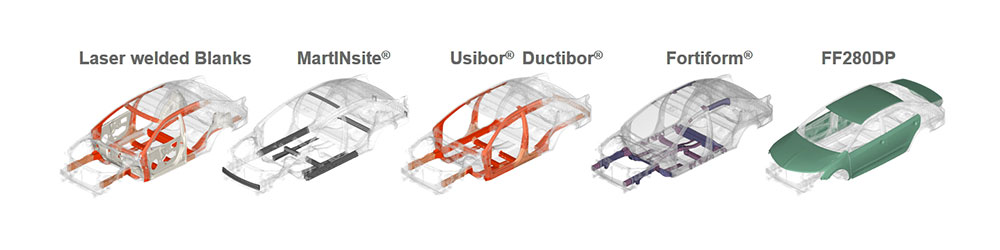

A new S-in motion® study from ArcelorMittal has identified potential weight savings of up to 25 percent on the body-in-white of European D-segment vehicles by compared with recent models. The new study in the S-in motion® suite uses the latest advanced high strength steels (AHSS) from ArcelorMittal including Usibor® 2000 and Ductibor® 1000. Emerging grades from the Fortiform® range have also been considered.

The D-segment S-in motion® study expands on a 2015 project which looked at the lightweighting potential of steel in mid-size sedans for the North American market. In the D-segment study, which uses European standards for structural performance, multiple options have been identified for each component of the vehicle structure including the body-in-white, closures, and hang-on parts. Both hot and cold stamping options are identified in many cases. All solutions are available to carmakers anywhere in the world thanks to ArcelorMittal’s global footprint and proximity to major carmakers.

The steels tested in this S-in motion® study are cutting-edge – some of the new Fortiform® grades which are utilised in this project are still to go into full production, while Usibor® 2000 and Ductibor® 1000 have just been released. ArcelorMittal’s new grades in the Fortiform® family have proven perfect to meet the lightweighting challenge of S-in motion®. But in addition to its lightweighting potential, Fortiform® also offers high strength and excellent response to cold forming operations.

As well as new automotive steel grades, ArcelorMittal is expanding its portfolio of automotive coatings. One of the latest is Jetgal® which was developed to protect very high strength cold rolled products such as Fortiform® and MartINsite®. These grades, coated with Jetgal®, are particularly useful for structural applications in the car underbody where higher strength is required. The galvanic corrosion protection provided by Jetgal® can be an asset for some OEMs in these applications.

ArcelorMittal’s latest S-in motion® study again shows that advanced steels can be the solution to the lightweighting challenges carmakers face – and at a very cost-effective price.

To find out more