ArcelorMittal Europe – Flat Products

ArcelorMittal Europe – Flat Products

Royal Dutch Mint creates an iconic new building with Granite® Silky Shine

Read more

One area where this is critical is digitalisation. We already offer many digital tools which allow customers to choose the most suitable solutions to optimise their relationship with ArcelorMittal. But we recognise that our advanced solutions do not fit all customers.

For smaller customers, we are testing a robot which can scan orders from emails and faxes automatically. The robot translates the customer’s request into an SAP order. This speeds up the order process and gives customers access to the benefits of digital tools without the need to make investments or change existing processes.

Logistics and scheduling are other areas where we are making major improvements to be closer to customer needs. Again, we recognise that different customers have different needs and we tailor our logistics offer accordingly.

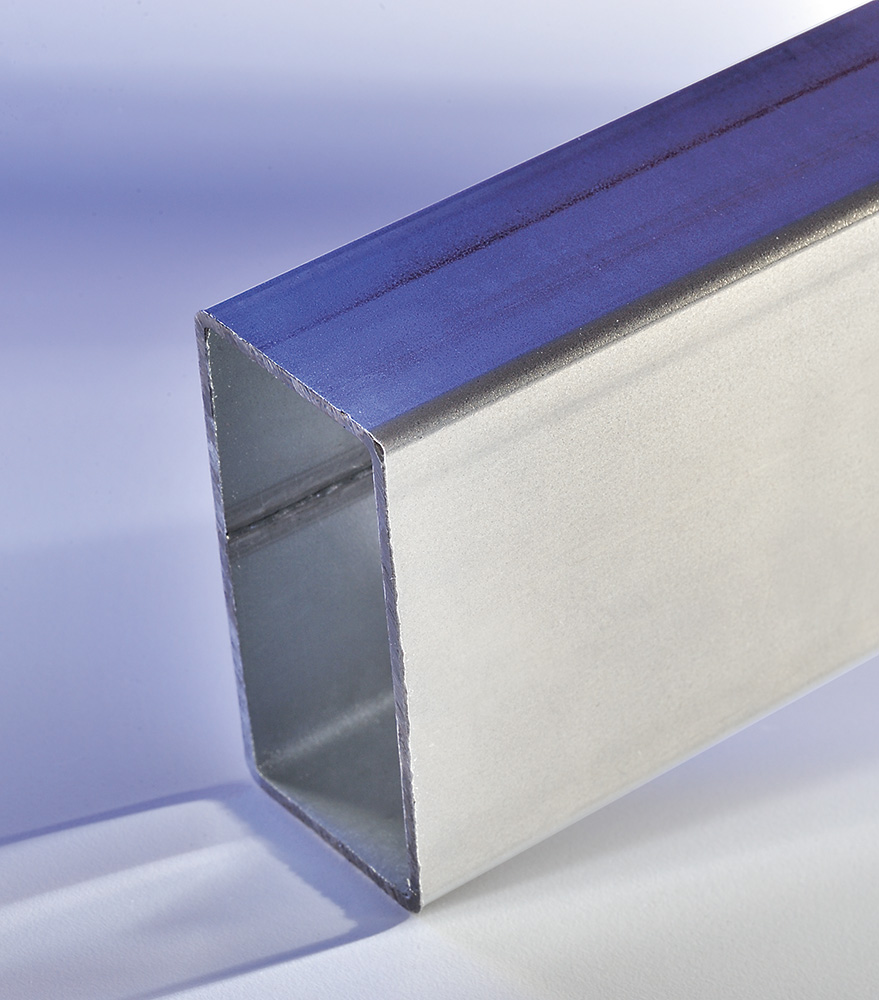

We are also developing new coatings which meet the needs of individual businesses. Our highly regarded Magnelis® coating is a good example. Magnelis® has been widely adopted because of the long-term protection it offers against corrosion. It is also better for the environment as Magnelis® uses less zinc than traditional galvanised coatings and zinc runoff to soil and water is minimised.

A new range of Magnelis® will be launched this year. It offers a lighter coating and will replace some traditional galvanised steels. The range will reduce zinc use even further, without affecting the performance of the coating.

Our steels are also being improved to meet customer needs. ArcelorMittal’s Amstrong® range of high strength steels for industrial machinery is a prime example. Replacing thicker commodity grades with a thinner and stronger Amstrong® grade means that customers consume less steel to make the same product. Coupling our steels with co-engineering support helps customers to create smarter designs with thinner steel. That can result in weight reductions of up to 40 percent for many applications.

A new range of Magnelis® will reduce zinc use without affecting the coating’s performance