ArcelorMittal Europe – Flat Products

ArcelorMittal Europe – Flat Products

Markus Schempp,

General Manager of SAMAG Truck Components

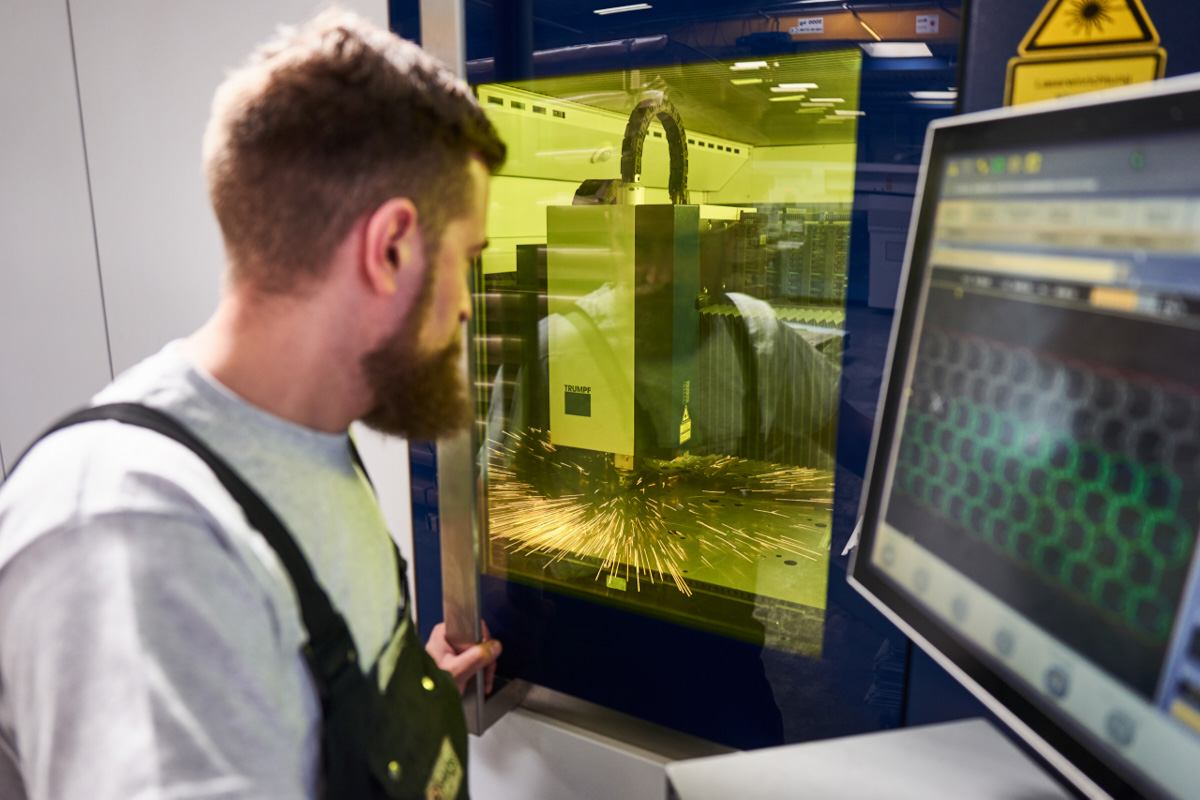

SAMAG Truck Components can produce almost every component of a truck chassis

For SAMAG, the benefits of working with a single steel supplier mean that ordering and manufacturing are simplified. “By working with ArcelorMittal for all our steel needs, we have optimised our sourcing and procurement processes,” notes Markus Schempp. “But it also means our operators can trust in the homogeneity of the material. With one machine set-up, they can apply the same process to the material from every batch.”

Another advantage of working with ArcelorMittal is our flexibility says Markus Schempp: “We are exposed to significant variations in demand from our customers. That means our steel supplier needs to ‘breathe’ with us and adapt to short-term changes in our forecasts and call-offs. This is possible thanks to the security stocks ArcelorMittal holds for us.”