ArcelorMittal Europe – Flat Products

ArcelorMittal Europe – Flat Products

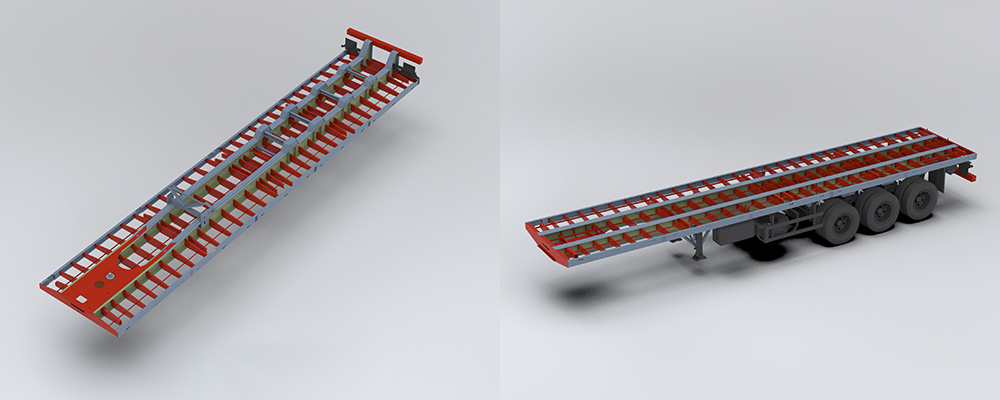

The reference chassis utilises structural grades such as Amstrong® 355MC

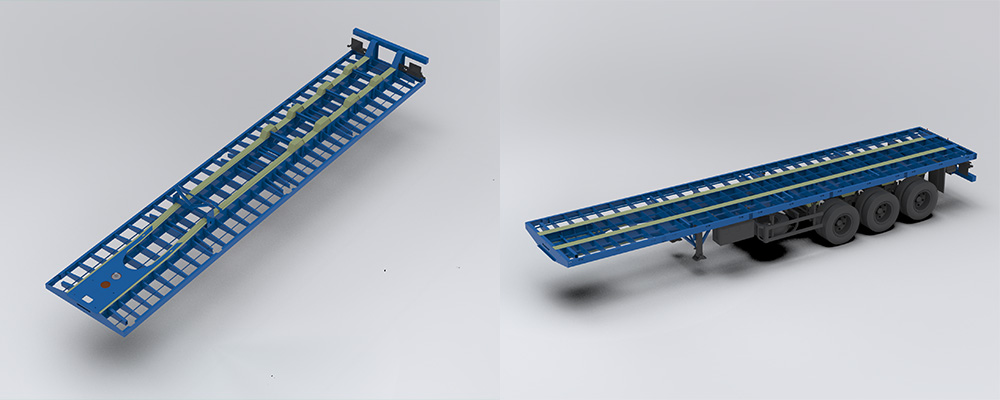

Deploying AHSS such as Amstrong® Ultra 700MC reduced the weight of the chassis by a quarter

A road trailer must withstand a huge amount of wear and tear over its lifetime.

Loading and unloading operations, combined with the effects of rough roads,

chemicals such as de-icing salts, and exhaust gases, quickly take their toll.

ArcelorMittal’s generic Trailtech solution makes extensive use of

Amstrong® 500MC

and Amstrong® Ultra 700MC – high-end steel grades which can withstand

fatigue – even

with the heavy use trailers receive.

The use of these grades enables the weight of the Trailtech solution to be reduced

by 25 percent compared to the reference trailer. ArcelorMittal Global R&D estimates

that this would cut fuel use by between 595 and 1,360 litres of fuel annually. The

reduction in fuel use decreases costs and could cut Scope 1 emissions by between

1,760 and 4,030 kg a year.

Additional cost and emission savings are possible due to the significant reduction

in steel required. ArcelorMittal estimates that material costs would be reduced

significantly. This would lead to a cut in Scope 3 emissions of around 25 percent

from reduced material production.

The new Trailtech design has been assessed against standards defined by TÜV Rheinland – a leading testing and certification body based in Germany. In all cases, the Trailtech solution met or exceeded the generic requirements.

To read the full article, please

Click here

More information on Amstrong® and Amstrong® Ultra

More info