ArcelorMittal Europe – Flat Products

ArcelorMittal Europe – Flat Products

ArcelorMittal’s MPI concept offers advantages in many areas of vehicle production

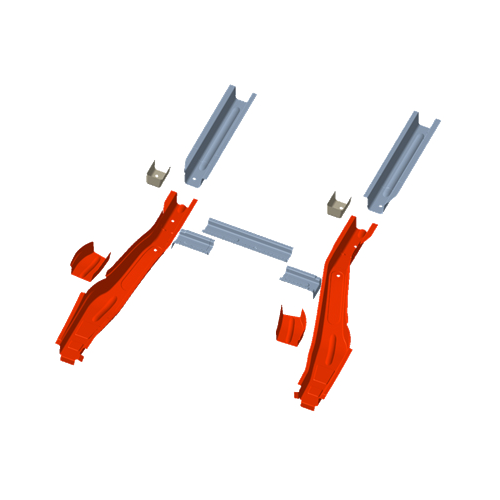

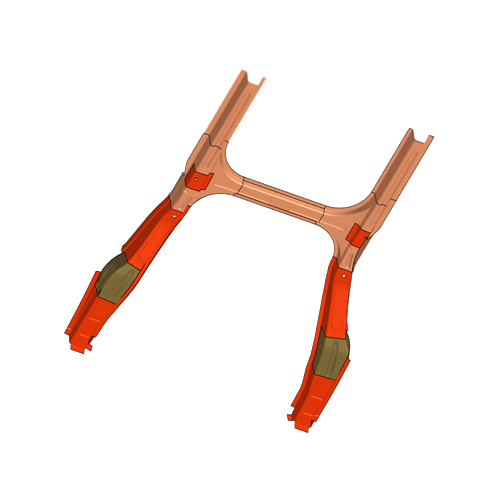

To prove the practical viability of the MPI concept, teams from ArcelorMittal

Tailored Blanks and ArcelorMittal Global R&D completed an MPI analysis of the rear

H-frame of an S-in motion® SUV vehicle. The MPI H-frame concept replaces

11 separate

parts with one. The solution can be applied to almost any powertrain simply by

adding patches to reinforce local areas.

The MPI H-frame concept showed that 136 spot welds could be eliminated for every

vehicle, and that the footprint of an OEMs bodyshop could be reduced by half. The

weight of each vehicle is also reduced by 1.4 kilograms which means less

CO2

emissions from reduced steel production and during the vehicle’s life. The

combination of LWB technology and PHS such as Usibor® and

Ductibor® has enhanced safety

and ensured that the H-frame concept passed global crash test scenarios.

The MPI rear H-frame reduced the number of separate parts from 11 to just one LWB

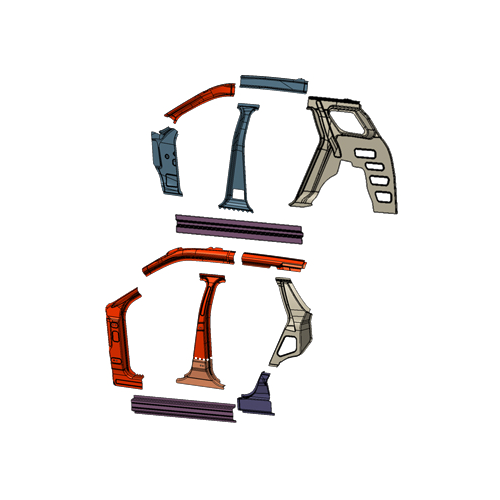

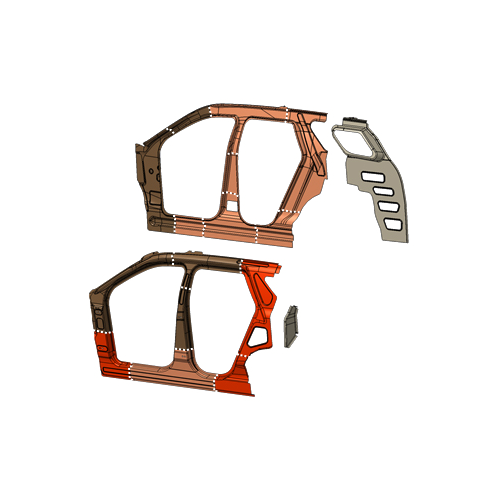

ArcelorMittal engineers have also applied the MPI concept to a double door ring.

The MPI concept combined a total of 13 parts on each side of the vehicle into

just four per side. The number of spotwelds was cut by 122 per side, or 244 over

the entire vehicle. Overall, the mass of the body-in-white is reduced by around 10 kilograms using the MPI design.

ArcelorMittal is now working on a new MPI concept for the floor panel. The

results of this study are expected to be announced later in 2021.

The H-frame, double door ring, and floor panel MPI applications have passed

relevant IIHS and Euro NCAP tests.

When applied to a double door ring, the MPI concept reduced the number of parts from 13 to 4 per side

ArcelorMittal believes that the MPI concept will offer a new dimension in vehicle evolution. Over the coming years, many more MPI applications will be identified and developed in cooperation with OEMs.

More info on MPI:

Read more