ArcelorMittal Europe – Flat Products

ArcelorMittal Europe – Flat Products

Discover why Corinth Pipeworks placed its largest ever order to ArcelorMittal. Read more

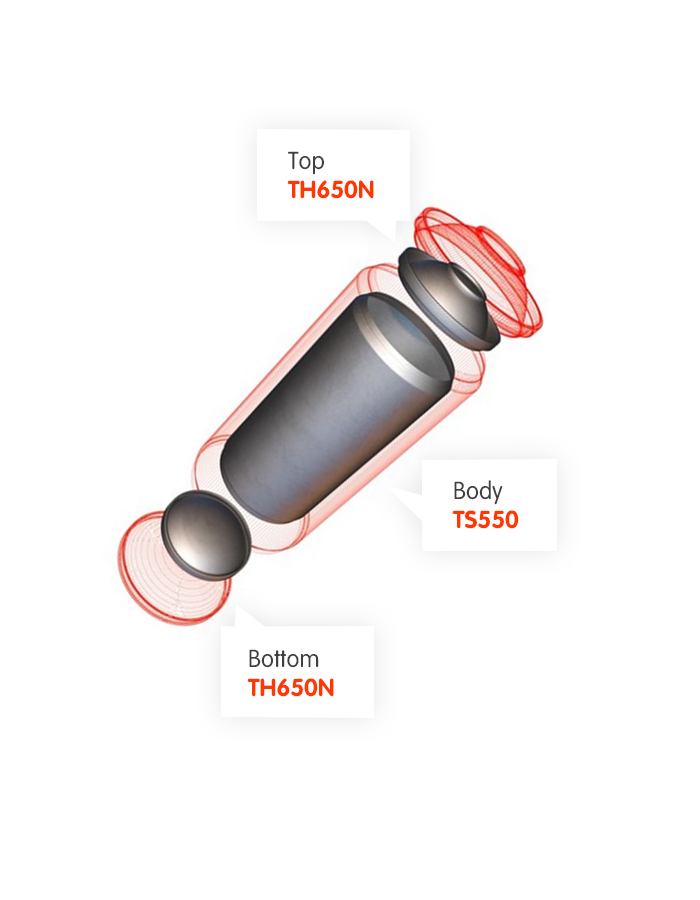

One of the key lessons from the first tests of the SI tool is that lightweighting is a direct way to reduce the environmental footprint of steel products at all stages of their lifecycle. The latest lightweighting project to be realised by ArcelorMittal is the introduction of two new packaging steel grades for three-piece aerosol cans.

By using these steels for all three parts of the aerosol, canmakers can achieve weight savings of up to 17 percent compared to existing solutions. The steels have very high strengths, allowing the downgauging of can components and reducing material use. Emissions from transportation are also lowered due to the lighter weight of the aerosol.

New aerosol grades introduced by ArcelorMittal cut the weight of three-piece aerosol cans significantly

Case study on 210 ml (brimful) / diameter 52 mm

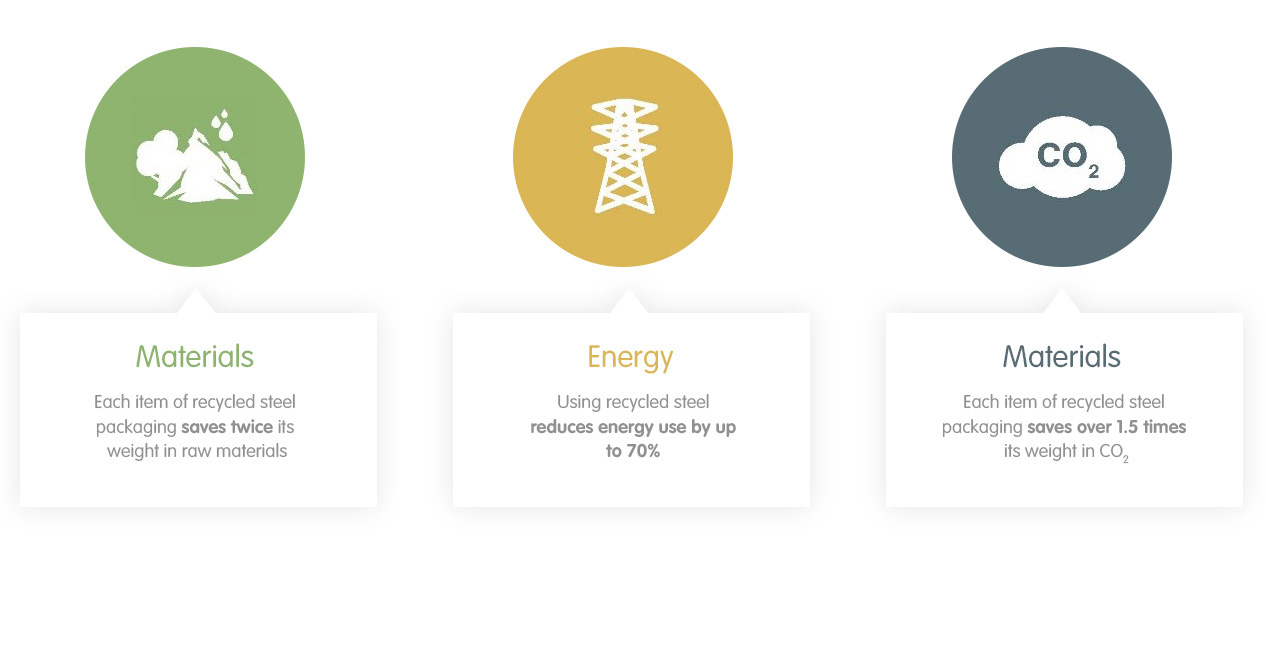

Minimising material use impact is a key goal of the European Union’s Circular Economy Package which aims to make the region’s economy more sustainable. The Package also sets new recycling targets for common packaging materials and includes provisions to create closed material loops which save resources such as materials and energy and reduce carbon emissions. While the targets are challenging for some materials, steel for packaging is already achieving many, making it the model material for a sustainable economy.

Steel packaging meets circular economy goals to reduce material and energy use, and emissions

Recent figures released by APEAL, the European association representing producers of steel for packaging, show that the recycling rate for steel packaging has reached a new high of 79.5 percent in 2016 – the latest year for which full statistical data is available. This is just below the 80 percent recycling target the EU requires steel to achieve by 2030.

Recycling steel for packaging reduces the energy required to produce new steel by 70 percent and saves twice its weight in raw materials. Each item of recycled steel packaging saves over one-and-a-half times its weight in carbon dioxide.

“While there is still more work to be done, it’s clear that steel for packaging is already a model material for the circular economy. And although it is one of the oldest packaging materials, further cooperation and innovation will ensure steel is the packaging material that will meet the challenges of the 21st century”, concludes

Anne-Laure Hettinger, Head of Sustainability, ArcelorMittal Global R&D.