ArcelorMittal Europe – Flat Products

ArcelorMittal Europe – Flat Products

The goal of S-in motion® is to identify cost-effective steel solutions OEMs can utilise to ensure their fleets meet emission regulation targets while maintaining vehicle safety, comfort, and performance. Several chassis applications were examined as part of S-in motion® – and the weight saving potential is significant.

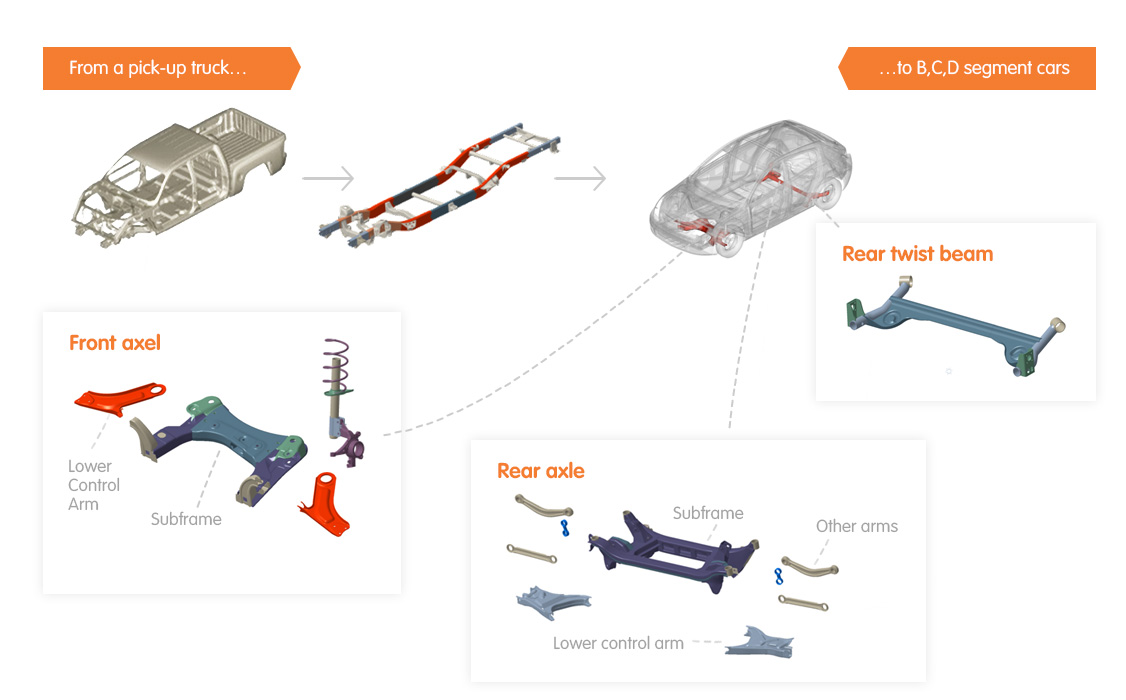

The scope of ArcelorMittal’s S-in motion® Chassis study covered both pick-up trucks and passenger vehicles

As part of the study, the most common chassis parts (such as lower control arms, front subframe, rear multi-link subframe, and rear twist beams) were redesigned using AHSS. Weight savings of between 15 and 26 percent were achieved.

Chassis parts must provide adequate stiffness for the vehicle while resisting cyclic, incidental, and accidental loads. They also need to resist the effects of aggressive corrosion environments as they are located close to the road. In order to meet these highly specific criteria, ArcelorMittal has developed AHSS for cold stamping with specific properties including excellent forming and fatigue properties.

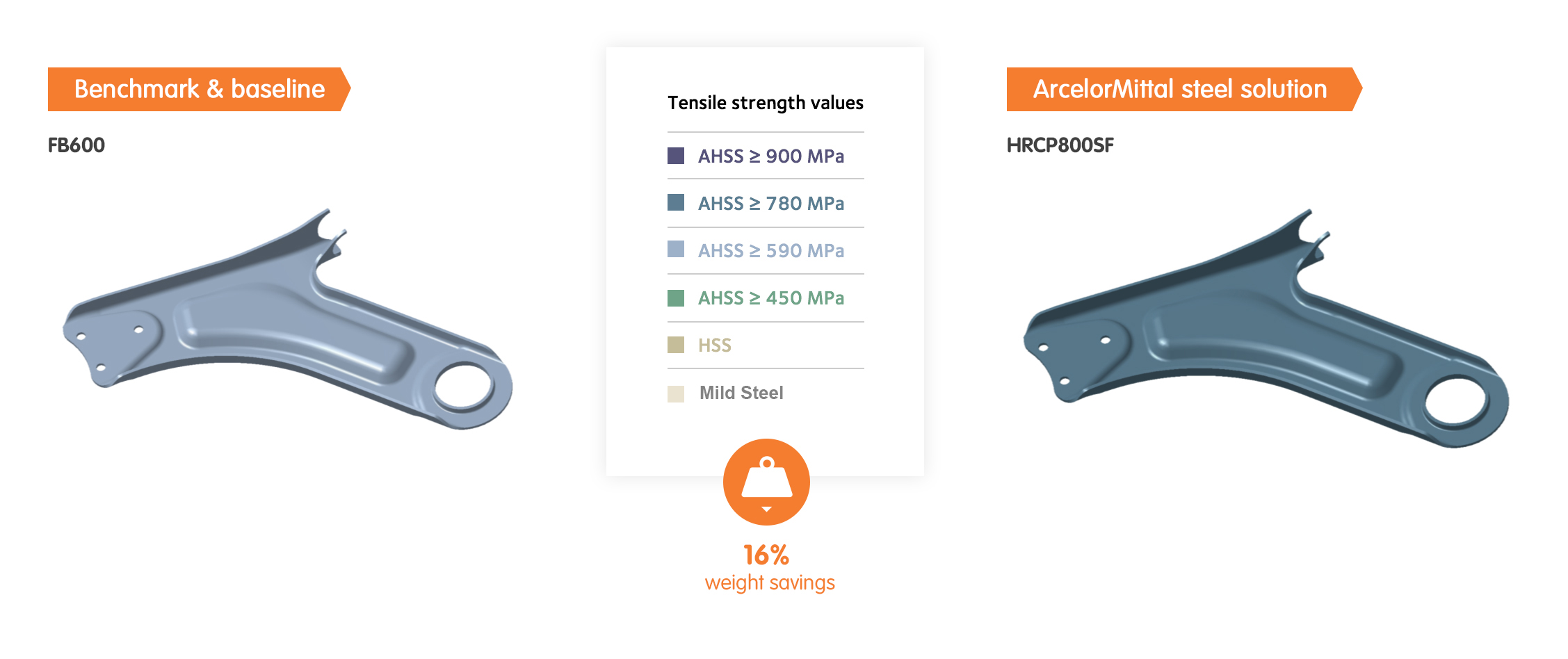

CP800SF was used to form the lower control arms, achieving a weight reduction of 16 percent compared to the baseline

During the development of these grades, the properties of the steels were optimised to facilitate the manufacturing of chassis components. The modifications enhanced cut edge formability and the hole expansion properties of the steels, allowing OEMs to design chassis parts with flanged edges and stretched holes.

The use of CP800SF and CP1000SF enabled the weight of the engine cradle to be reduced by 15 percent

The S-in motion® Chassis study also assessed hot stamping solutions. Hot stamped parts typically exhibit good geometry and better fatigue properties. The hot stamping process allows the design of more complex part geometries, fewer forming steps, and higher mass savings.

ArcelorMittal’s latest S-in motion® study for chassis components demonstrates again that significant weight savings are achievable at little to no additional cost using the latest AHSS. The steels are already available in most regions of the world and can be implemented in production vehicles today.

To read the full article,

Click here

Want to discover more best-in-class solutions for chassis applications?

View the webinar