ArcelorMittal Europe – Flat Products

ArcelorMittal Europe – Flat Products

A key requirement for the selection of the steel supplier was the width and properties of the coils required notes Nikolaos Sarsentis, procurement director at Corinth Pipeworks: “The customer specified the hot rolled grade API 5L X65M for their projects. However, the coils needed to be ultra-wide – up to 2.1 metres – and achieve API 5L standards. ArcelorMittal has the capacity, technical competence, and experience to reliably deliver high-quality steel for very large projects such as this.”

The hot rolled coils used to form the pipes were produced at ArcelorMittal Bremen (Germany) and ArcelorMittal Fos sur Mer (France). They were shipped to the Corinth Pipeworks manufacturing plant in Thisvi (Greece) where they were formed into

26-inch HFI pipes.

The finished pipes were coated externally to protect them from the elements before being shipped to the customer in Houston (USA). “Corinth Pipeworks America, based in Houston, provided the logistics to transport the pipes from the port to the customer’s marshalling yards,” says Nikolaos Sarsentis. “In total, more than 850 kilometres of pipes will be laid in two separate projects to transport oil across Texas.”

The recent addition of tariffs on European steel by the US came as the pipes were being produced in Greece and had a major impact on the project. Nikolaos Sarsentis explains: “The imposition of a 25-percent duty by the US government dramatically increased the cost of the project for our customer. However, no steel producer in the US could meet the customer’s specifications, particularly regarding width. And there are no

US pipe makers who can produce the pipes using HFI technology.”

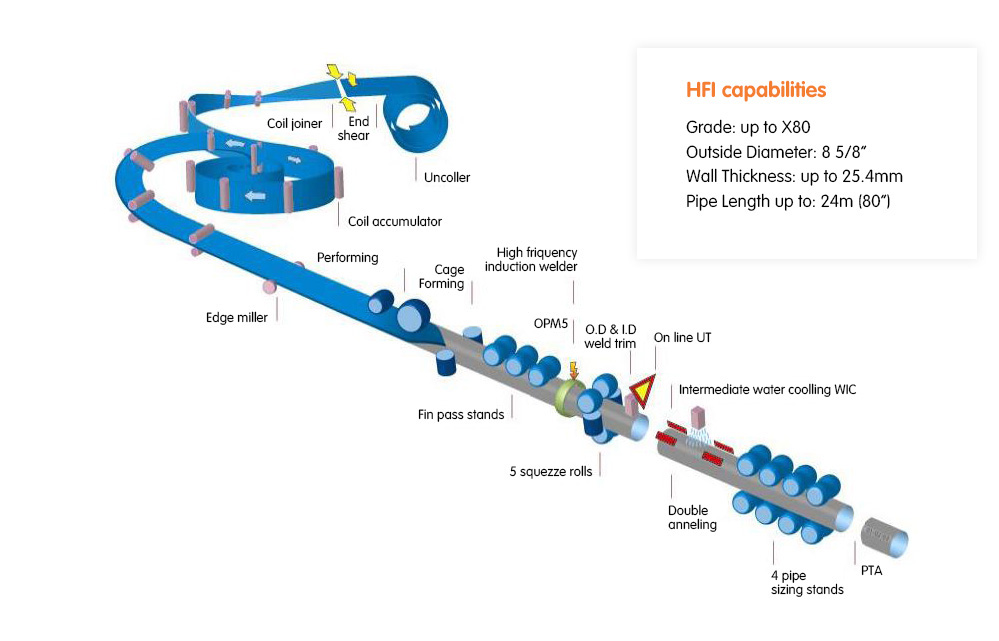

Corinth Pipeworks produces HFI welded pipes directly from the coil in a single, continuous process