ArcelorMittal Europe – Flat Products

ArcelorMittal Europe – Flat Products

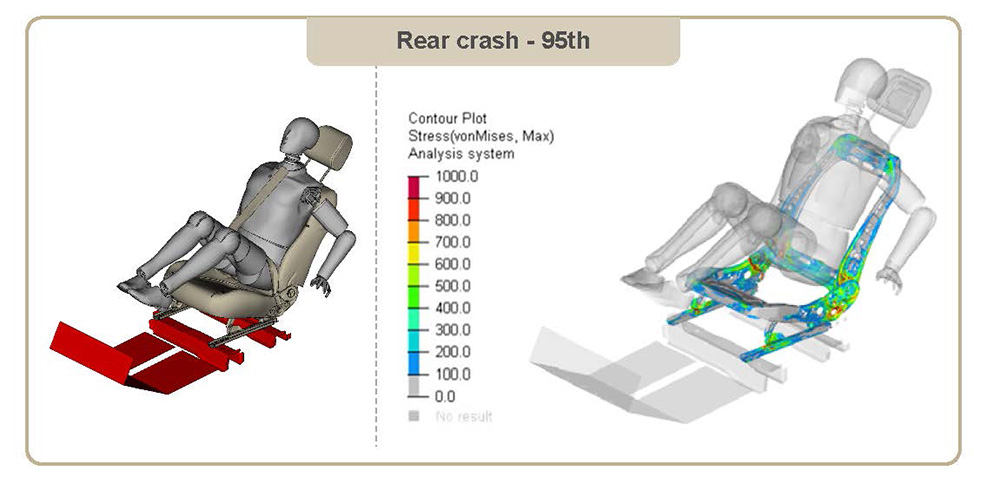

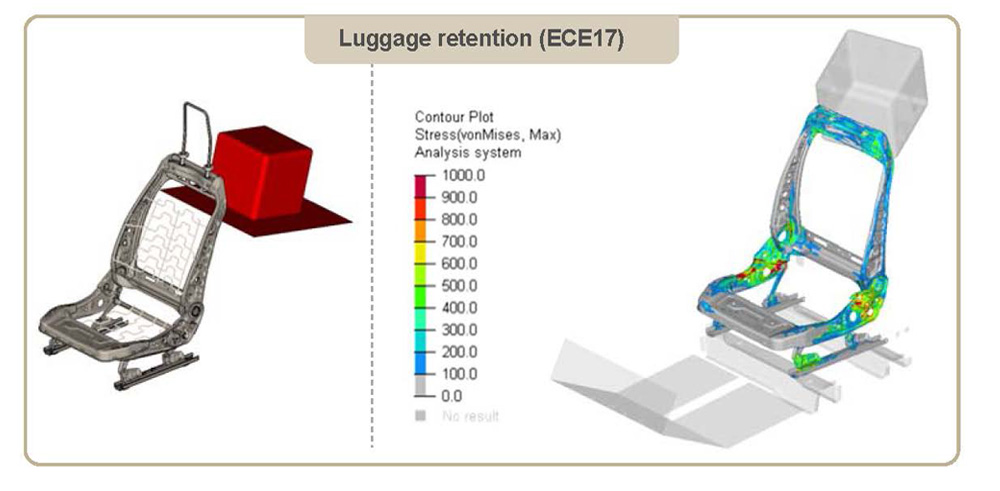

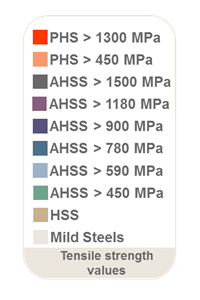

The S-in motion® Front Seats project identified where advanced high strength steels (AHSS) could be used to optimise and lightweight components while maintaining safety and performance. The scope of the study was a typical front seat for a C-segment passenger vehicle.

With commercially available seats weighing between 11.5 and 12.8 kilograms, the S-in motion® team first defined a baseline seat which weighed in at 12.4 kilograms. Their goal was to cut this to around 10 kilograms per seat using an optimised design and the latest AHSS.

The use of AHSS was combined with part redesign to take maximum advantage of the advanced mechanical characteristics of the new steels. These parts included the backrest side-member, cushion side-member, gusset, and brackets. Some parts, such as the backrest side-member were redesigned by the S-in motion® team to reduce the number of parts. This reduced both weight and assembly time without affecting safety.

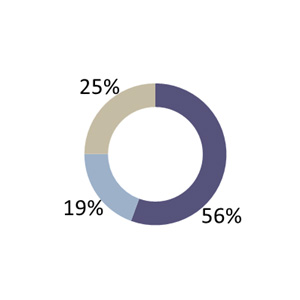

Two S-in motion® Front Seats designs were developed as a part of the project. The first – known as the Ultimate design – reduced the weight of the seat from 12.4 to 10.1 kilograms, a saving of 2.3 kilograms (18.3 percent) per seat. With two front seats, the total saving could be 4.6 kilograms per vehicle.

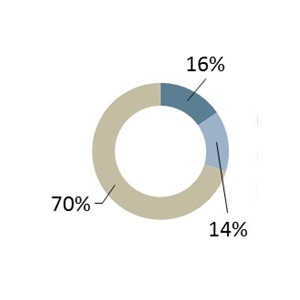

The second solution – the Efficient design – reduced the weight of the seat to 10.4 kilograms, a saving of 2.0 kilograms (15.5 percent) per seat. However, this solution is achievable at a slightly lower cost to manufacturers. In high-volume production (over half a million seats per year), both S-in motion® Front Seats designs can reduce costs.

To find out more about S-in motion® Front Seats solutions:

Click here

Mouse over to discover the weight reduction per piece

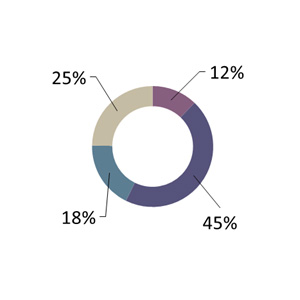

Potential weight savings for each component of the Ultimate S-in motion® Front Seats

Baseline mass = 12.4 kg

Efficient Concept = 10.4 kg

Ultimate Concept = 10.1 kg