ArcelorMittal Europe – Flat Products

ArcelorMittal Europe – Flat Products

ArcelorMittal has developed the new generation iCARe® steels in response to strong demand from the automotive market for better electric vehicles. Using second generation iCARe® grades, torque density can be increased by two percent. This has a significant impact on the use of battery power and driving range.

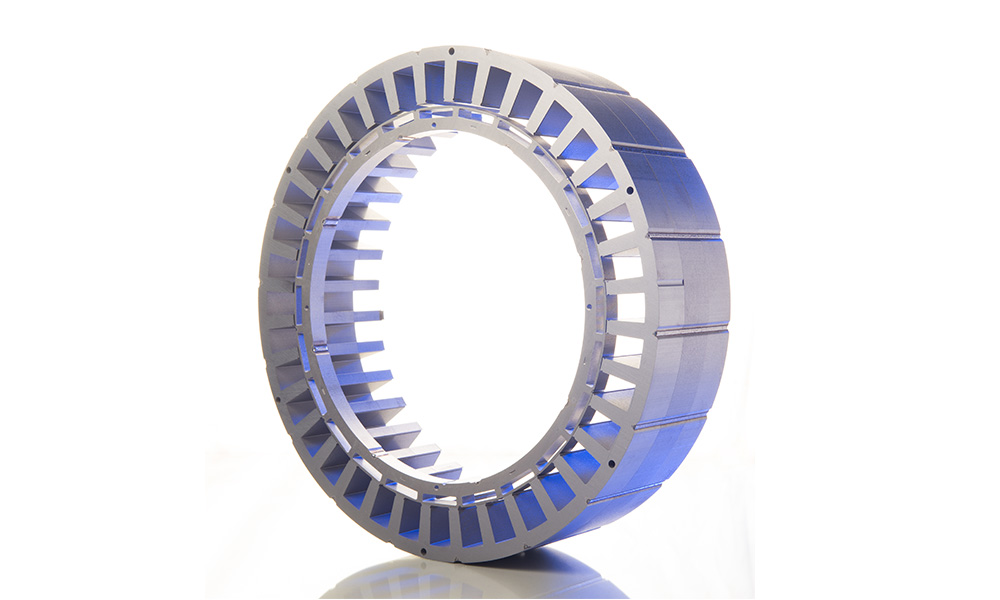

iCARe® is ArcelorMittal’s offer for electrical machines

“With the second generation of iCARe® we have increased efficiency by 0.7 percent for a motor with a reference efficiency of 96 percent,” explains Sigrid Jacobs, electrical steels portfolio director for ArcelorMittal Global R&D. “While it might not sound like a big increase, it means we can make motors that are 1.6 percent smaller than ones made from standard steel. When you consider there are up to 70 electric motors in an average vehicle, operating everything from headlight controllers to windscreen wipers, that can translate into a significant weight reduction and greater driving range.”

For electric vehicle makers, second generation iCARe® steels offer a choice between reducing the size of their machines to achieve the same performance level, or keeping the machine size the same to increase performance and greater driving range.

The latest iCARe® steels enable OEMs to create smaller motors and increase driving range

The latest iCARe® steels also have applications in any industry which requires highly efficient motors notes Salih Ozkan, chief marketing officer for electrical steels at ArcelorMittal Europe – Flat Products: “Green energy generation is one area that would benefit hugely from our new iCARe® steels. Wind and hydroelectric generators require engines which can operate constantly with low energy loss over a long service life. The better the electrical steel, the greater the amount of renewable energy they can generate.”

Electrical steels are highly alloyed steels with exceptional electromagnetic properties. “The dynamic developments in electric mobility is demanding a great deal of innovation from us,” notes Sigrid Jacobs. “We’re continuing to research new innovations in the field which will enable our customers to meet the demands of the market.”

For more information about ArcelorMittal’s iCARe® range of electrical steels for mobility solutions, please visit: http://automotive.arcelormittal.com/icare

iCARe® steels have been specifically developed for use in electric engines. They allow engine designers to create: